BN2520 es un material de revestimiento de caucho metálico típico, utilizado principalmente en la fabricación de juntas de múltiples capas, el revestimiento de caucho es un revestimiento de caucho de nitrilo con excelente resistencia al aceite, y el sustrato de metal es 301 de acero inoxidable. También llamamos a este material de metal suave, podría hecho de placa de hierro delgada, placa de acero inoxidable, placa de aluminio u otra placa de metal recubierta con caucho sintético. Combina la rigidez del metal y la elasticidad del Caucho y se puede utilizar como piezas de automóviles, piezas de la máquina, piezas de equipos electrónicos y así sucesivamente. La temperatura máxima de operación a corto plazo para BN2520 podría alcanzar hasta 250 ℃.

| Propiedad | Especificación | |

| Tipo de caucho | NBR | |

| Tipo de metal base | SUS301 | |

| Apariencia superficial | Semi-brillo negro | |

| Espesor total (mm) | 0,25 ± 0,02 | |

| Base Matel espesor (mm) | 0,20 ± 0,01 | |

| Espesor de revestimiento de caucho (mm) | 0.025 + 0.005 (por lado) | |

| Max. Operación Temp (℃) | ≤ 150C | |

| ASTM-D3359 de prueba de adherencia de la puntuación | 100% residual | |

| ASTM-D4541-09 de prueba de extracción (MPa) | ≥ 1,4 | |

| Dureza de metal base (HV) | 430 ~ 470 | |

| Físicos sin edad | D-2240 ASTM Shore A duromete (puntos) | 70 ~ 80 |

| Resistencia a la tracción Mpa (Min.) ASTM D-412 | ≥ 8 | |

| Alargamiento definitivo (% min) D-412 ASTM | ≥ 200 | |

| Calor Envejecido (70 hrs @ 100 "C) | Cambio en la dureza del durómetro (puntos) D-573 ASTM | -15 ~ 15 |

| Cambio en la resistencia a la tracción (% máx.) D-573 ASTM | -30 a 30 | |

| Aceite de cambio de volumen (% máx.) IRM 903, D-471 ASTM | ≤ 40 | |

| Revestimientos de caucho | |

| Caucho de nitrilo butadieno (NBR) | Un caucho sintético con excelente resistencia a los aceites, refrigerante, combustible, refrigerante y otros fluidos. NBR ofrece una resistencia a la abrasión superior para la adherencia metal-acero. Resistencia al calor hasta 200 ↑en la acción del Estado de campe |

| Foamet de caucho de nitrilo butadieno (NBR) | Las mismas características de NBR, con el beneficio especial de una mayor conformidad con las superficies de sellado rugosas y las aplicaciones de carga de pinza más baja. |

| Caucho fluoroelastómero (FKM) | Resistencia al calor superior y rendimiento de inmersión fluida. Resistente al calor hasta 250 * C en aplicaciones de estado con abrazadera. |

| CORES DE METAL | |

| Acero inoxidable | SUS301, 3% duro, completamente duro. SUS201 |

| Acero laminado en frío | SPCC,1/4 duro. C490 |

| Aluminio | |

| RECUBRIMIENTO SUPERFICIAL DE LIBERACIÓN | |

| PTFE | Revestimiento de superficie de alto rendimiento |

| Resina | Revestimiento antiadherente |

Resistencia de aceite:El caucho NBR tiene una excelente resistencia al aceite, lo que lo hace adecuado para su uso en varios sistemas de aceite lubricante, aceite combustible y otros sistemas que contienen aceite.

Resistencia a la abrasión:El caucho NBR tiene buena resistencia a la abrasión, que puede soportar la fricción y el desgaste de alta velocidad.

Resistencia al calor:El caucho NBR tiene buena resistencia al calor y puede soportar altas temperaturas de hasta 100 ° C.

Resistencia química:El caucho NBR tiene buena resistencia química y puede soportar la mayoría de los ácidos, AlkaLIS, y sales.

Elasticidad:El caucho NBR tiene buena elasticidad y puede recuperar su forma original después de ser estirado o comprimido.

Aislamiento eléctrico:El caucho NBR tiene buenas propiedades de aislamiento eléctrico y es ampliamente utilizado en la producción de componentes eléctricos y materiales de aislamiento.

Propiedades de procesamiento:El caucho de nitrilo butadieno NBR tiene buenas propiedades de procesamiento.

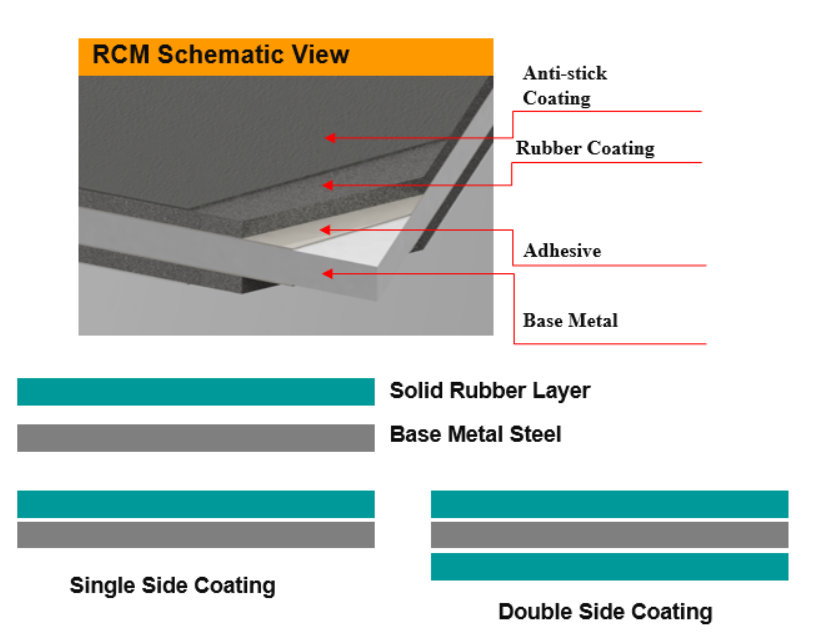

El material metálico recubierto de caucho (RCM) tiene una amplia gama de aplicaciones.

1. Industria automotriz: RCM se puede utilizar para hacer autopartes, como juntas, piezas de amortiguador, piezas de sistema de suspensión, etc. Debido a la buena flexibilidad y resistencia al desgaste de los compuestos de caucho metálico, puede amortiguar y absorber eficazmente la vibración causada por los golpes de la carretera, mejorar la comodidad y la estabilidad de conducción. Al mismo tiempo, el caucho metálico también puede evitar que el agua, el polvo y otras sustancias externas ingresen al interior del automóvil, mejore el sellado del automóvil. Además, la tecnología de procesamiento de revestimientos de caucho metálico también se puede extender desde la Unión de caucho y metal a la Unión de caucho y plástico y tela de fibra. Con el aumento de los tipos de productos compuestos y la expansión del campo de aplicación, los requisitos para la tecnología de Unión son cada vez más altos, y la perspectiva de aplicación de los recubrimientos de caucho metálico es amplia.

2. maquinaria industrial: este material se puede utilizar para el sellado de componentes en maquinaria pesada que operan en condiciones duras, tales como turbinas, calderas, e intercambiadores de calor.

3. industria de petróleo y gas: BN2520 se puede utilizar en la producción de sellos y juntas para tuberías, válvulas y otros equipos que manejan fluidos de alta presión y alta temperatura.

Tenga en cuenta que estas son recomendaciones generales basadas en las condiciones generales de operación. La idoneidad del material para una aplicación específica debe determinarse mediante pruebas y análisis adicionales. Siempre consulte con el ingeniero de materiales de Teamful Sealing para obtener asesoramiento adaptado a sus necesidades específicas.